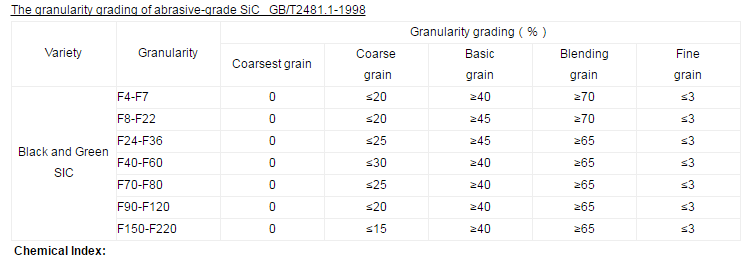

Abrasive-grade SiC size for different standards

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Short Ton |

Basic Info

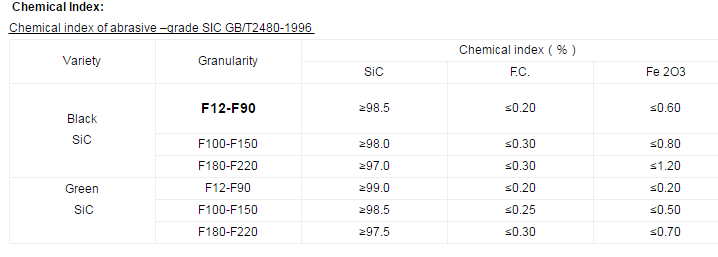

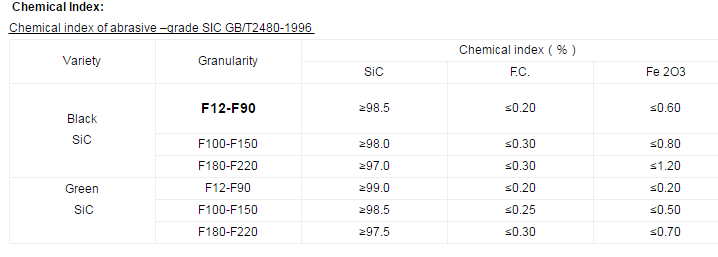

Model No.: F12-F90Black SiC-98.5

Additional Info

Packaging: bag

Productivity: >10000ton

Transportation: Ocean,Land

Place of Origin: Ningxia China

Supply Ability: >100000ton

Certificate: standard

Port: Port of Shanghai,Port of Shenzhen,Port of Tianjin

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF

Product Description

Abrasives are sharp, hard materials that grind softer material surfaces. Abrasives with natural abrasive and artificial abrasive two broad categories. According to the hardness of the super-hard abrasive and general extra-abrasive two categories. Abrasives range from softer household detergents, gem abrasives to the hardest material diamonds. Abrasive materials are indispensable for the manufacture of every precision product. Many natural abrasives have been replaced by artificial abrasives.

Due to its stable chemical properties, high thermal conductivity, small coefficient of thermal expansion and good wear resistance, silicon carbide has many other applications besides abrasive materials. For example, silicon carbide powder can be coated on the turbine wheel or the cylinder block in a special process The inner wall can improve its wear resistance and extend the service life of 1 to 2 times; to be made of advanced refractories, heat shock, small size, light weight and high strength, energy-saving effect.

China smelting silicon carbide production technology, technology and equipment and single ton of energy consumption reached the world's leading level. Black and green silicon carbide quality level is also a world-class block. China's silicon carbide and the world's advanced level of the gap is mainly concentrated in four areas: First, seldom use large-scale machinery and equipment in the production process, many processes rely on manpower to complete, lower per capita production of silicon carbide; the second is in silicon carbide deep-processing products , Fine grained sand and fine powder product quality management is not fine enough, the stability of product quality is not enough; Third, the performance of some cutting-edge products compared with similar products in developed countries there is a certain gap; Fourth, the direct emissions of carbon monoxide in the smelting process.

China green silicon carbide smelting is the main origin of Gansu, Qinghai, Xinjiang and Sichuan. Sichuan is mainly powered by hydropower stations. Due to the shortage of electricity in the dry season, the production time in one year is only in April-October and the longest can sustain production for 6 months. However, the smelting furnaces in Sichuan hardly ever started normally, mainly because the market Weak demand, inventory is difficult to consume. In the first three quarters of 2012, the operating rate of Chinese steel mills was relatively low. Only after the steel mills increased their operating rates after October, the consumption of raw materials and refractory materials increased slightly and some inventories were consumed.

China origin

⑴ as abrasive, can be used to make abrasive, such as grinding wheel, Whetstone, grinding head, sand tile and so on.

⑵ as a metallurgical deoxidizer and high temperature materials.

⑶ high purity single crystal, can be used in the manufacture of semiconductors, manufacturing silicon carbide fibers.

The main purpose: for 3-12 inch monocrystalline, polycrystalline silicon, potassium arsenide, quartz crystal wire cutting. Solar photovoltaic industry, semiconductor industry, piezoelectric crystal industry, engineering materials.

For semiconductor, lightning rod, circuit components, high temperature applications, UV detectors, structural materials, astronomy, disc brakes, clutch, diesel particulate filter, filament pyrometer, ceramic film, cutting tools, heating elements, nuclear fuel , Jewelry, steel, protective gear, catalyst carrier and other fields.

Mainly used in the production of grinding wheel, sandpaper, abrasive belt, whetstone, grinding block, grinding head, grinding paste and photovoltaic products in monocrystalline silicon, polycrystalline silicon and piezoelectric crystal and other aspects of the industry, such as grinding, polishing and so on.

Product Categories : Chemicals Products > Carbon Products